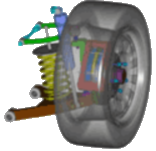

Dynamic Designer Motion

Motion Simulation embedded in Solid Edge

Motion/Professional Applications

Evaluate an unlimited number of design alternatives before you build and test a physical prototype.

Size motors and actuators

If you use motors, you have probably experiences problems like underestimating peak motor torques, failure to account for dynamic structural loading during machine operation, unable to predict the performance of non-linear systems and long/xpensive workout periods for prototype machinery. Dynamic Designer can solve these problems.

Determine power consumption

Determing actuator power consumption is immediately available in an XY plot. Power consumption is a quantity calculate from the motion simulation results.

Determine boundary conditions for stress analysis

If you are like most companies you use experience and guesses as boundary conditions for your FEA. Make FEA more than just a guess. Use the loads from Dynamic Designer to improve the accuracy of your FEA.

Friction

See how friction will increase power requirements and actuators size.

Force Transmission

Understand how forces are transmited through a mechanical system.

Spring and Damper Stiffness

You can see the effect of spring/damper systems on system motion, quickly experiment with spring/damper rates, and model non linear spring/damper effects.

Hydraulic actuators

Understand the forces required for hydraulic actuators.

Reduce vibrations

Identify vibration problems and reduce them using elements like motion dampers.

Understand unbalance effects on mechanisms

You will see how a unbalanced mass can effect the motion and how it transmits loads throughout the system.

Understand bearing loads

Make sure your mechanism does not exceed the loading conditions for your flat, ring, or ball bearings.

Quote

Quote Evaluation

Evaluation